INDUSTRIAL MONITORING

In recent years it was necessary to change the world of production, through the integration of digital technologies and management processes, with particular attention to energy savings and predictive monitoring of events. The ability to communicate enhances the production line with self-diagnostic and remote control capabilities. In addition, the smart factory allows to control energy consumption and to reduce costs and wastes. Canavisia, a Seica Company has developed a non-invasive smart system providing continuous monitoring of the status of industrial machines, foreseeing possible failures while optimizing production processes and costs.

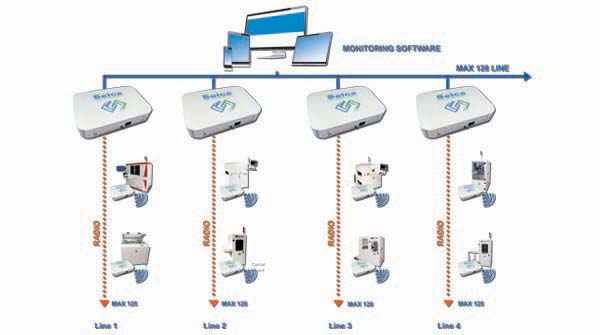

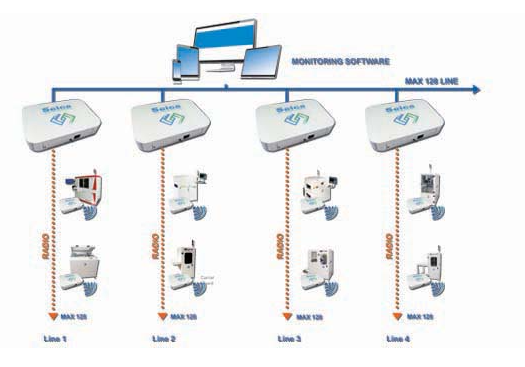

Each machine in the line is equipped with an electronic control unit that communicates via wireless with the SysMaster. The SysMaster is responsible for receiving and processing data sent from individual control units and for sending the information to the management computer.

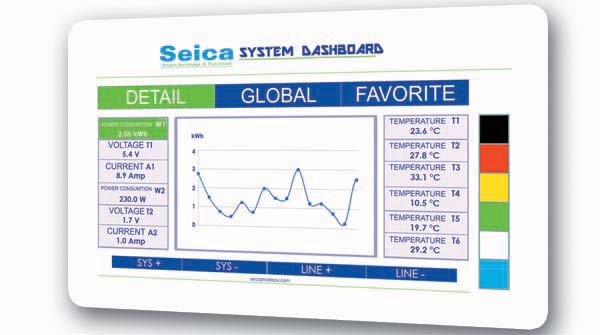

Prevention of possible malfunctions due to wear that might lead to machine downtime is essential for time optimization and to improve ordinary and extraordinary maintenance management. These goals are achieved by adopting appropriate management, monitoring and control systems. Sensors provide the capability to monitor both the working status of a machine and the real-time condition of the production line. The installation of vibration, temperature and pressure sensors, will allow the user to know the machine faults in advance and to intervene timely before the machine downtime occurs. The current and voltage monitoring allows the user to check the amount of current supplied to the line. This highly-advanced technology is not invasive and can be applied to any type of machine, regardless of the manufacturer or of the function. For energy saving purposes, the “start and stop” procedure can be activated when the machine is not used for a preset time (only if the machine is configured for this procedure).

Seica Suite Software

The in dustrial monitoring saves time, and provides a comprehensive overview of the status of production line.

dustrial monitoring saves time, and provides a comprehensive overview of the status of production line.

The tables below represent the Seica Suite interface. All the sensors are displayed by a control software in a Windows platform with the possibility to customize the user notifications.