Conformal Coating Inspection

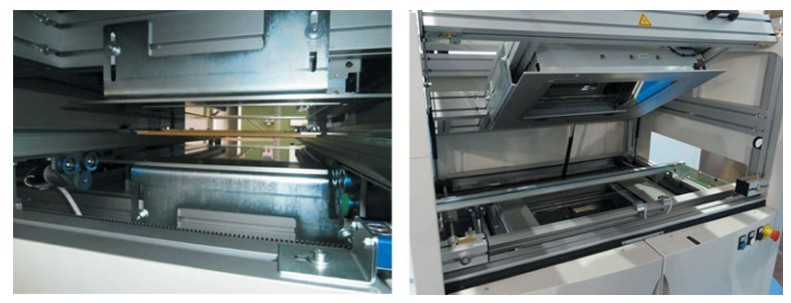

The Dragonfly CC Next> series ensures a quick and complete examination of all coated assemblies.

The combination of multi-colored LED lighting, UV-LED lighting with the color line scan camera enables clear Laquer Inspection.

The full-scan imaging of the PCB will ensure proper detection of faults. Compared to manual inspection, the results of Dragonfly CC Next> series are not operator dependent, but always objective and reproducible.

The inspection allows rapid feedback of process faults (closed-loop).

The test results are displayed for documented repair of the module at the appropriate repair station. This results in time and cost savings as well as a significant increase in quality.

• Dragonfly CC Next> series saves time, space and money.

• The typical payback is eight to twelve months

To receive a flawless end product and at the same time reduce the costs for quality control and on-going basis, inspection is required to make sure faults do not arise. AOI (Automatic Optical Inspection) allows an economical test of various processes.

Automatic and manual fabrication steps can therefore be verified using many diverse criteria. There is a demand for a flexible solution; it should provide a test with different requirements in mind and without an elaborate and complicated test program process. The program generation can be done in minutes.

Process optimization

Utilising Dragonfly CC Next> series for conformal coating not only detects faults like missing areas and splash contamination but also helps with process control. Initial coating programs can be checked and fine-tuned to create uniform coating patterns with an even thickness. Existing processes can be monitored for changes during the production run. A blocked nozzle or a material change can easily be spotted.

In order to detect conformal coating defects, it is necessary that the coating material has an UV trace. The product has to illuminate with UV light and using the fluorescent light for the inspection.

Our solution use an High Power UV LED source to amplify the response of applied product and have a better result in testing.